Related

High Temperature (HT) Nozzle and Valve Repair

Overview

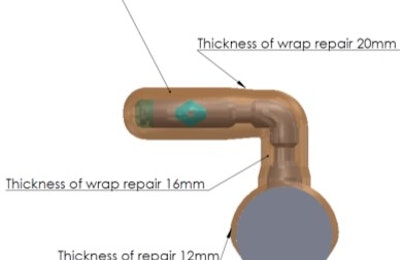

A valve on a header line had developed a leak, however, as the valve and nozzle were no longer required for operation, the leak was sealed and made safe by encapsulating both the valve and nozzle. Traditional repairs methods could not be used as the line was required to remain live during repair.

The temperature requirement required a heat tape to provide an elevated temperature (8000C) cure.

Scope

The line had the following specifications:

| Structure | Header Line Valve |

| Surface Preparation | Sa 2.5 |

| Class Approval | N/A |

| Design Pressure | 5,800 kPa |

| Design Temperature | 1000C |

| Application Temperature | 200C |

| Design Life | 20 years |

| Wrap Length | 500 mm |

| Pipe Diameter | 50 mm |

| Geometry | Wrap over valve, nozzle and header line |

| Corrosion Type | Internal |

| Defect Details | 5 mm circumferential slot (through-wall) |

Solution

- Technowrap 2K™ HT system with temperature capability up to 220°C

- The repair was designed taking into account the complicated geometry and limited landing areas around the valve and nozzle arrangement

- Heat tape required for elevated temperature cure

Benefits

- Repair completed without hot works

- No impact on production, line remained live during the repair

- Versatility in application delivering a patched design solution, rather than a typical wrap repair creating a more cost effective solution

- Documented QA/QC procedures provide a complete record of the repair materials and application process for future reference