Related

External Corrosion High Temperature (HT) Repair

Overview

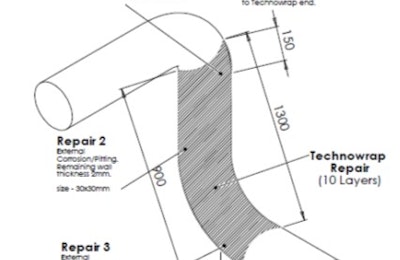

Corrosion under insulation resulted in significant external wall loss on an onshore hydrocarbon processing line.

A rapid repair with high temperature and complex geometry capabilities was required immediately to bring the line back into service.

Scope

The line had the following specifications:

| Structure | Demethaniser pipework |

| Surface Preparation | Sa 2.5 |

| Design Pressure | 3,790 kPa |

| Design Temperature | 1210C |

| Application Temperature | 200C |

| Design Life | 2 years |

| Wrap Length | 1,300 mm |

| Pipe Diameter | 200 mm NB |

| Corrosion Type | External |

| Defect Details | Circumferential wall loss |

| Post Cure | Yes - heat tapes |

Solution

The solution to this project was:

- Technowrap™ 2K HT system with temperature capability up to 220°C

- Heat tapes used to provided post cure temperature of 60°C-80°C

- Heat tapes were used around the clock, to meet rapid delivery requirements of client

Benefits

The benefits of executing this solution were:

- Repair completed with rapid engineering and site delivery, within 24 hours

- No impact on production, line remained live

- Documented QA/QC procedures provide a complete record of the repair materials and application process for future reference