Related

Produced Water Repair Over Clamp on FPSO

Overview

Internal corrosion had caused a through wall defect to a produced water line. The defect had been temporarily repaired with a Plidco Smith type clamp, however the Client required a repair with a 10 year design life extension and ABS class approval.

TechnowrapTM is the only composite repair class approved by ABS and Lloyds.

Scope

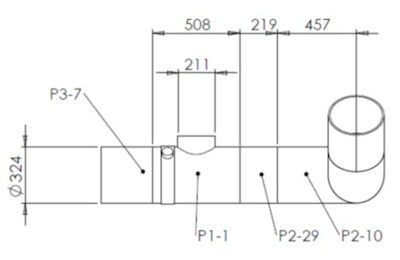

The line had the following specifications:

| Structure | Water Line |

| Surface Preparation | Sa 2.5 |

| Class Approval | ABS |

| Design Pressure | 1,650 kPa |

| Design Temperature | 800C |

| Application Temperature | 500C |

| Design Life | 10 years |

| Wrap Length | 1.15 m |

| Pipe Diameter | 324 mm |

| Geometry | Wrap over clamp and T |

| Corrosion Type | Internal |

| Defect Details | (e.g. 65mm circumferential (through wall) |

Solution

- Technowrap 2KTM HA system with temperature resistance up to 90°C

- Wrap installed over existing temporary clamp

- Designed to accommodate significant internal corrosion over the life of the repair

- Detailed QA/QC procedures captured repair details for future reference

Benefits

- Repair completed on a live line without the need for a shut-down or any production loss

- No hot works required

- Flexibility in TechnowrapTM technology allowed for complicated geometries to be repaired, such as a clamp and tee shaped pipework

- QA/QC processes ensured high quality wrap to be installed and documented